Luxury steel fire tables that bring people together.

Peak 26 offers high end gas burning fire tables for your residential or commercial outdoor space. Our Steel Fire Tables offer sharp precision and modern lines in a variety of shapes and sizes.

Steel Fire Tables to withstand any environment.

Our steel fire tables have been designed and built to provide decades of enjoyment. Steel will withstand extreme temperature fluctuations without spalling or cracking, can be moved and transported without settling and is the superior choice for strength, durability and raw beauty. Precision handcrafted in Utah with aircraft tolerance fixture tables and industry-leading CNC equipment, there is no compromise made for quality in building our fire tables. An elegant backyard focal point.

Inspired by simple elegance and functional design styles, a Peak 26 Fire table is the focal point in any yard.

Product Gallery

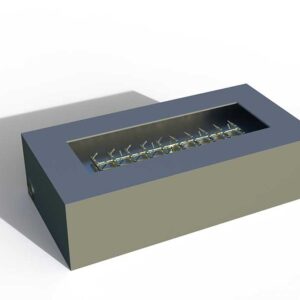

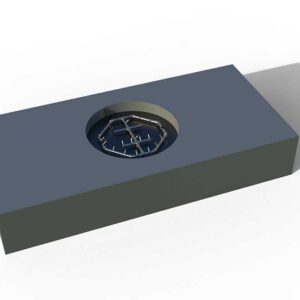

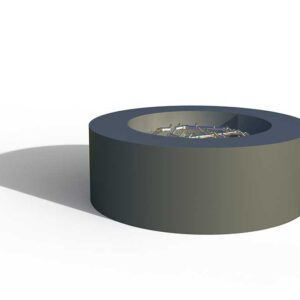

Denali

La Sal

Ranier

Shasta

Teton

Timp

Wasatch

Don't take our word for it.

Send us a message.

Our Process

Peak Plasma Design offers high end gas burning fire pits for your residential or commercial outdoor space. Our pits offer sharp precision and modern lines in a variety of shapes and sizes.

- Design

- Processing

- Build

- Features

- Powdercoating

Peak 26 utilizes both 3D renderings for final design as well as 2D CAD to coincide with our plasma table. We test each and every size of joint prior to final build to ensure overall dimensions are as real and precise as the rendering. After the design is complete and the needed panes are nested onto a 4×8 digital sheet, we transfer the cut code over to our arclight dynamics CNC plasma table.

Peak 26 utilizes both 3D renderings for final design as well as 2D CAD to coincide with our plasma table. We test each and every size of joint prior to final build to ensure overall dimensions are as real and precise as the rendering. After the design is complete and the needed panes are nested onto a 4×8 digital sheet, we transfer the cut code over to our arclight dynamics CNC plasma table.

We start with American made 3/16” hot rolled mild steel sheet sourced in Salt Lake City, UT. The sheets are carefully transported to our production shop in Kamas, UT, a short drive from Park City. Extra care is taken to ensure no scratches are present and the steel remains clean and flat. Sheets are then loaded onto our Arclight Dynamics CNC Plasma table via a magnetic winch. One our program is loaded our hypertherm plasma cutter goes to work. We use the finest of hypertherm consumables to ensure a perfect cut out of our machine. Once the sheets are cut into the parts to construct the pit they are unloaded by hand and any dross is chipped off with a wire wheel.

We start with American made 3/16” hot rolled mild steel sheet sourced in Salt Lake City, UT. The sheets are carefully transported to our production shop in Kamas, UT, a short drive from Park City. Extra care is taken to ensure no scratches are present and the steel remains clean and flat. Sheets are then loaded onto our Arclight Dynamics CNC Plasma table via a magnetic winch. One our program is loaded our hypertherm plasma cutter goes to work. We use the finest of hypertherm consumables to ensure a perfect cut out of our machine. Once the sheets are cut into the parts to construct the pit they are unloaded by hand and any dross is chipped off with a wire wheel. We chose to invest in a .001 flatness fixture table to alleviate any worry of an uneven table surface. Our pits are constructed by two metal fabricators with 30+ years of combined experience. We work in unison almost reading each other’s minds while creating these fire burning pieces of art. All of the joints are pulled tight utilizing specialty tooling and expertise. Once the pit is complete the edges are all touched with a high speed high grit sanding disk to take down any overhangs or irregularities.

We chose to invest in a .001 flatness fixture table to alleviate any worry of an uneven table surface. Our pits are constructed by two metal fabricators with 30+ years of combined experience. We work in unison almost reading each other’s minds while creating these fire burning pieces of art. All of the joints are pulled tight utilizing specialty tooling and expertise. Once the pit is complete the edges are all touched with a high speed high grit sanding disk to take down any overhangs or irregularities. Peak 26 fire pits offer the strength and precision that will keep them looking as flat and sharp as the day they arrive to your home or business. We use internal gussets on all corners, thick gauge steel to alleviate any bows over long stretches, and structural cross braces to tie in the burner apparatus of your choice.

Peak 26 fire pits offer the strength and precision that will keep them looking as flat and sharp as the day they arrive to your home or business. We use internal gussets on all corners, thick gauge steel to alleviate any bows over long stretches, and structural cross braces to tie in the burner apparatus of your choice.

We work closely with one of the best powdercoaters in the Salt Lake City valley that shares our passion for precise high end finishing. The pits are driven to salt lake and receive great care when in the hands of our powdercoaters. The pits are blasted with a special media made specifically for mild steel and then cleaned thoroughly to ensure the best adhesion once powdered. Any remaining lint from cleaning is baked off in the oven and then a zinc rich primer coat is applied using Electrostatic deposition. The pit is then baked in a large oven at 325-450 degrees to cure. One the primer is cured the process is repeated with the final color and cured again. Once out of the oven the part is left to cool and is now finished. Podercoating offers superior durability and a long lasting finish to metal surfaces. Our pits are coated inside and out and will offer the best durability available.

We work closely with one of the best powdercoaters in the Salt Lake City valley that shares our passion for precise high end finishing. The pits are driven to salt lake and receive great care when in the hands of our powdercoaters. The pits are blasted with a special media made specifically for mild steel and then cleaned thoroughly to ensure the best adhesion once powdered. Any remaining lint from cleaning is baked off in the oven and then a zinc rich primer coat is applied using Electrostatic deposition. The pit is then baked in a large oven at 325-450 degrees to cure. One the primer is cured the process is repeated with the final color and cured again. Once out of the oven the part is left to cool and is now finished. Podercoating offers superior durability and a long lasting finish to metal surfaces. Our pits are coated inside and out and will offer the best durability available.